The term “particle size reduction” means exactly that - the process of reducing average particle size in a given substance.

Homogenization is one kind of particle size reduction.

It is a process that uses mechanical force to break down particles or droplets in a liquid into smaller and more uniform sizes. The result of homogenization is a dispersion, where fine particles of one substance are scattered throughout another substance.

Dispersions can be further classified by the sizes of these types of particles:

- Solution: a homogenous mixture with tiny particles of a molecular size (e.g. sugar in water).

- Suspension: a heterogeneous mixture with large particles that will often settle out on standing or can be filtered out (e.g. sand in water).

- Colloid: a mixture that is somewhere in between a solution and a suspension. An emulsion is a type of colloid and is a mixture of two immiscible (unmixable) liquids. The first liquid forms tiny particles scattered throughout the second liquid. Oil and water, for example, will form an opaque suspension when mixed, but will separate on standing.

Particle size reduction through homogenization has countless applications in many industries including food, pharmaceutical, biotechnology, cosmetic and more. A common example of a homogenized liquid is milk. In the days before homogenization, milk naturally separated, and a layer of fatty cream would rise to the top; leaving what was essentially skim milk below. Homogenization is used to break up the fat globules into smaller droplets so that they remain suspended in the milk, creating an even, homogenous mixture.

Pion Inc.: Your Partner in Particle Size Reduction

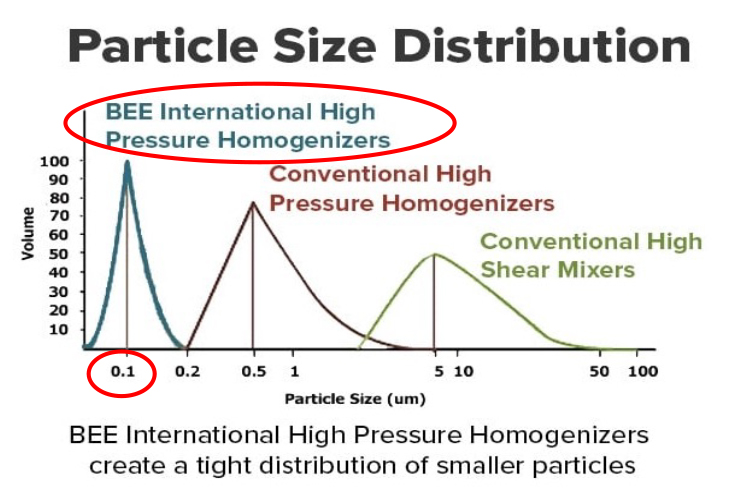

Pion is the supplier of BEE brand high pressure homogenizers. The BEE difference lies in the fact that we synergistically combine and fine-tune all available mechanical forces (including turbulence, cavitation, shear, impact and process intensity) in order to produce the best possible product for you. We produce a tight distribution of small, uniform particles every time. Depending on your product, benefits include a longer shelf life, increased bioavailability, improved sensory characteristics, and greater productivity and lower manufacturing costs due to fewer passes.

Our laboratory, pilot and industrial homogenizers all produce reliable and consistent particle size reduction.

Contact us and we would be excited to develop a customized solution just right for you.

Want to know more about particle size reduction? Download our FREE eBook: How to Achieve Efficient & Consistent Particle Size Reduction.